Industrial Hoses

Hoses are one of our outstanding products. Both the composite type and the rest of the rubber hoses are subjected to the necessary tests in our laboratory.

Filters

Do you need technical advice?

What industrial hoses are and what they are used for

Industrial hoses are flexible components designed for the safe transfer of fluids, gases or bulk materials in industrial installations. They are used as an alternative to rigid piping when it is necessary to absorb movement, vibrations, thermal expansion, or to facilitate loading, unloading and connection between equipment.

An industrial hose must ensure tightness, mechanical strength and compatibility with the conveyed product, even under demanding operating conditions. For this reason, correct hose selection is a key factor for the safety, efficiency and durability of any industrial installation.

Types of industrial hose and selection criteria

There are different types of industrial hoses, designed to adapt to the requirements of each process. Choosing the right hose depends on several technical factors that must be evaluated together.

The main selection criteria include:

- Chemical compatibility with the conveyed fluid or material.

- Working pressure and possible pressure peaks.

- Service temperature, both of the product and the environment.

- Flexibility and required bend radius.

- Environmental conditions and frequency of use.

Based on these parameters, an industrial hose can be manufactured in different materials and configurations, optimising its performance and service life.

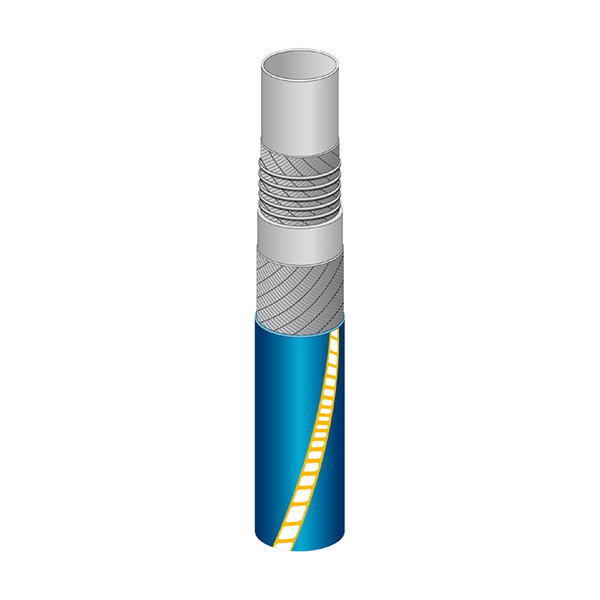

Construction and reinforcements in industrial hoses

The construction of an industrial hose is generally based on three main elements: an inner tube, a reinforcement and an outer cover. Each of these components fulfils a specific function in the overall performance of the hose.

The inner tube ensures compatibility with the conveyed product, the reinforcement provides pressure resistance and structural stability, and the outer cover protects against abrasion, external agents and environmental conditions. The correct combination of these elements determines the reliability of the hose in service.

Industrial applications of industrial hoses

Industrial hoses are used in a wide range of sectors and applications where flexibility and safety are essential:

- Transfer of water, oils and industrial fluids.

- Conveyance of air and gases.

- Processes in the chemical and petrochemical industries.

- Applications in the food industry, general industry and services.

- Loading, unloading and transfer operations.

In all these cases, the industrial hose acts as a critical system component, making its quality and suitability for the process essential.

Advantages of using high-quality Gassó industrial hoses

The use of high-quality industrial hoses offers clear advantages compared to improvised or unsuitable solutions:

- Improved operational safety and risk reduction.

- Ability to absorb vibrations and movement.

- Reduced stress on equipment and connections.

- Greater durability and reduced maintenance requirements.

- Optimisation of costs throughout the installation’s life cycle.

Integration with industrial systems and accessories

An industrial hose should not be considered an isolated component, but part of an assembly that includes couplings, fittings, flanges and connection systems. Correct integration between the hose and its accessories is essential to ensure tightness and proper system performance.

Gassó provides complete solutions that facilitate the integration of industrial hoses into new or existing installations, ensuring full compatibility between all components.

Gassó manufacturing, quality control and technical support

As a specialist in fluid transfer solutions, Gassó applies strict technical criteria in the selection, manufacture and supply of industrial hoses. Each solution is approached from a practical perspective, taking into account the customer’s real operating conditions.

Quality control, technical expertise and specialised support allow Gassó to deliver reliable industrial hoses, adapted to each application and designed for safe, long-term operation.

Standards, safety and service reliability

Industrial hoses are designed to meet the usual requirements of industrial installations and applicable standards depending on the sector. Correct material selection and process control ensure reliable performance even in demanding applications.

Gassó: industrial hoses for every application

With extensive knowledge of the industrial sector, Gassó offers industrial hoses adapted to a wide variety of processes and environments. The combination of product range, technical advice and experience makes Gassó a reliable partner for the design and maintenance of safe and efficient industrial installations.