Rubber Hoses

Wide range of industrial rubber hoses for all sectors.

Filters

Do you need technical advice?

Rubber hoses: why they remain the most versatile industrial solution

Rubber hoses continue to be one of the most widely used solutions in industry for the transfer of fluids, gases and bulk materials. Their combination of flexibility, mechanical strength and adaptability to different operating conditions makes them a key component in many industrial installations.

A properly selected rubber hose offers excellent resistance to abrasion, vibrations, impacts and movement, making it especially suitable for applications where rigid piping is not viable or presents operational limitations.

Types of industrial rubber hose by application

Industrial rubber hoses are designed according to the application and the product to be conveyed. In practice, the most useful classification is based on real use within the installation:

- Food-grade rubber hoses, for suction and delivery of liquid and semi-liquid products.

- Steam hoses, designed to operate at high temperatures and pressures.

- Chemical hoses, intended for broad compatibility with industrial chemicals.

- Rubber hoses for hydrocarbons and fuels.

- Rubber hoses for abrasive materials and solids in suspension.

- Rubber hoses for water and air, for general industrial and service applications.

This wide range of applications explains why industrial rubber hoses remain a reference solution across many different industrial sectors.

How to select industrial rubber hoses safely

Proper selection of an industrial rubber hose is essential to ensure system safety and durability. Not all rubber hoses perform the same way under identical operating conditions.

Some of the key selection criteria to consider include:

- Type of product and chemical compatibility of the compound.

- Working pressure and possible pressure peaks.

- Temperature of the fluid and the environment (especially for steam or bitumen).

- Use in delivery or suction (vacuum conditions).

- Abrasion, bend radius and environmental conditions.

A prior technical assessment helps prevent premature failures, production downtime and unnecessary risks.

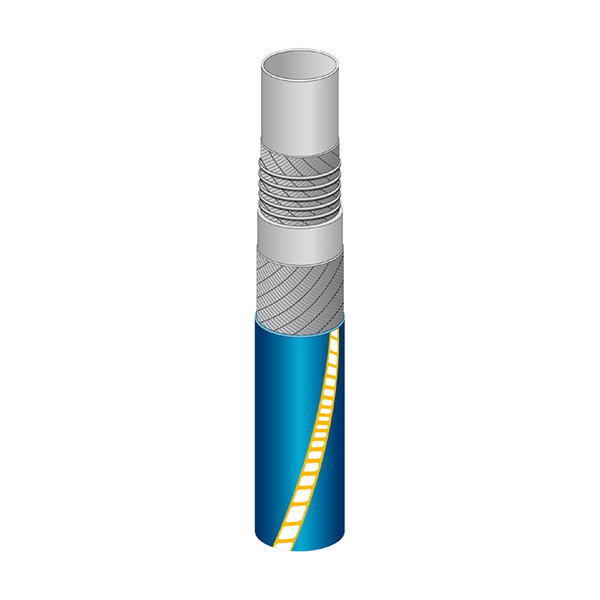

Structure of an industrial rubber hose

The construction of an industrial rubber hose is generally based on three main elements: inner tube, reinforcement and outer cover. Each component plays a specific role in the overall performance of the hose.

The inner tube determines product compatibility, the reinforcement provides pressure resistance and structural stability, and the outer cover protects against abrasion, chemical agents, ozone and environmental conditions. The quality and combination of these layers define the hose’s reliability in service.

Common rubber compounds and their performance

Industrial rubber hoses can be manufactured using different compounds, selected according to the application:

- EPDM, commonly used for steam, hot water and certain chemical applications.

- NBR, used in hoses for oils, fuels and hydrocarbons.

- SBR, frequently used in abrasion-resistant and general-purpose applications.

- Butyl (IIR) and other specific compounds, depending on particular requirements.

Final compatibility always depends on the compound formulation and the actual operating conditions.

Suction and delivery: a key difference

Not all rubber hoses are designed to operate under suction. When vacuum conditions are present, the hose must incorporate specific reinforcements, such as metal spirals, to prevent collapse.

Correctly distinguishing between delivery and suction applications is essential to ensure hose service life and system safety.

Highlighted applications in the Gassó rubber hose range

Gassó offers a broad range of industrial rubber hoses designed for specific applications, including food-grade hoses, steam hoses, solutions for chemical products, abrasive materials and bitumen.

This application-driven approach makes it possible to select the most suitable rubber hose for each process, avoiding generic solutions that may not meet real industrial requirements.

Connections, fittings and assembly: a complete solution

An industrial rubber hose must be part of a safe assembly that includes appropriate fittings, couplings, flanges and fastening systems. An incorrect combination of components can compromise safety even when the hose itself is correctly selected.

Gassó provides complete solutions that ensure compatibility between hoses and connections, enabling safe and reliable integration into the installation.

Safety, standards and traceability

Many applications involving industrial rubber hoses are subject to specific standards, particularly in sectors such as food processing, steam, chemical and hydrocarbons. Using hoses designed to meet these requirements is essential for safe operation.

Traceability and technical documentation provide added value in regulated industrial installations.

Gassó experience and technical support

Gassó goes beyond product supply. Its experience in fluid transfer solutions allows it to offer technical advice focused on selecting the most suitable industrial rubber hose for each application.

This technical support, combined with broad product availability, makes Gassó a reliable partner for industrial installations that require service continuity and operational safety.

Gassó rubber hoses: a range for every industrial sector

The rubber hose range from Gassó covers a wide spectrum of industrial applications. From general uses to highly demanding processes, Gassó’s industrial rubber hoses are designed to deliver reliability, durability and safe performance in service.