Top and Bottom Loading Arms

The only Spanish manufacturer of top and bottom loading arms for land and rail terminals.

Filters

Do you need technical advice?

Loading arms: what they are and what they are used for

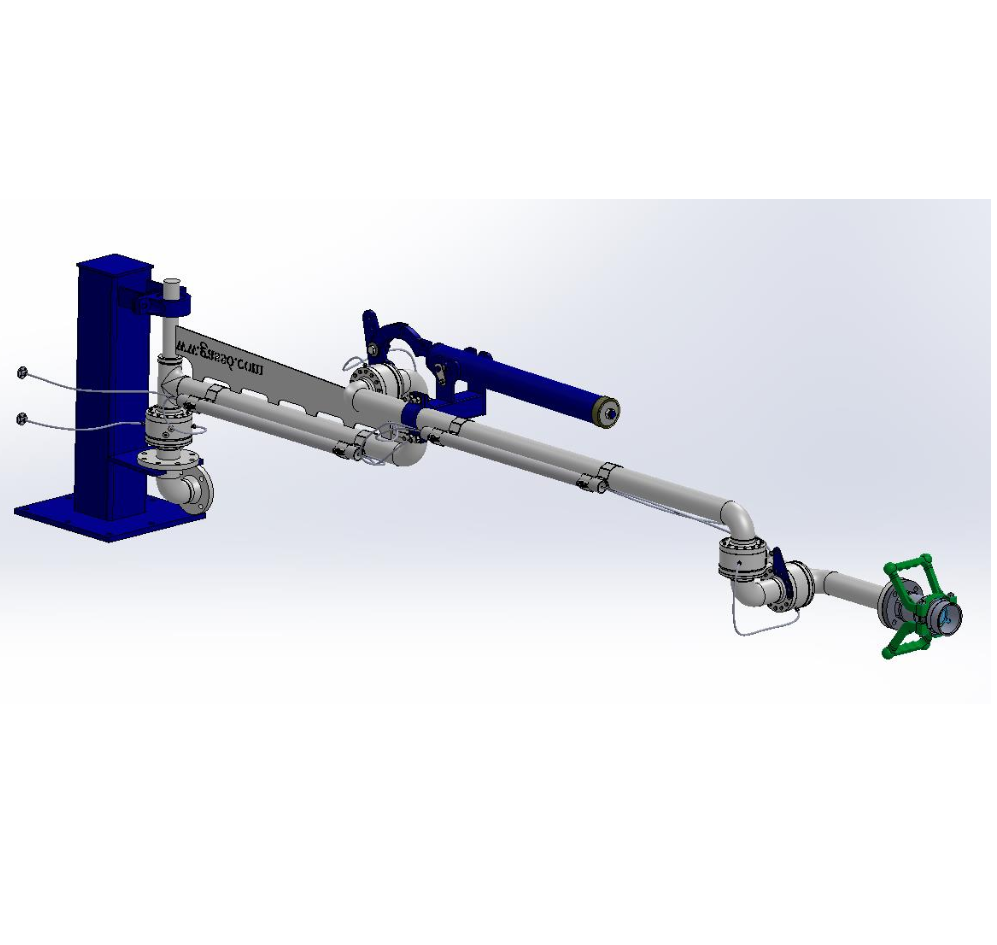

Loading arms are systems designed to carry out the safe loading and unloading of fluids between fixed installations and tank trucks, rail tank cars or containers. Their main purpose is to ensure a controlled, tight and reliable connection during transfer operations, reducing operational risks, spills and manual handling efforts.

As a manufacturer with extensive experience in fluid transfer solutions, Gassó designs and supplies loading arms adapted to demanding industrial environments, where safety, reliability and durability are critical factors. For this reason, loading arms are an essential element in storage terminals, industrial plants, refineries, chemical facilities and port installations.

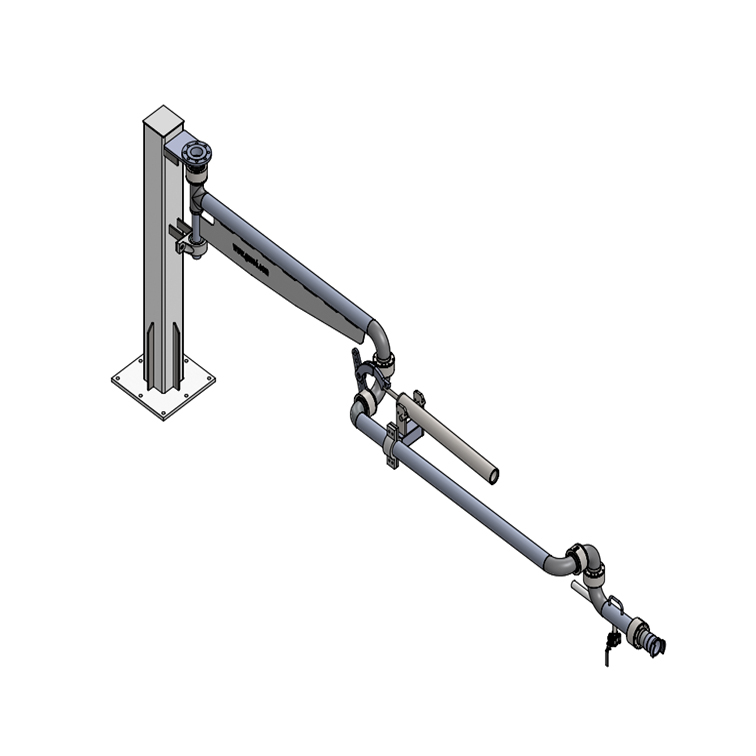

Top loading arms and bottom loading arms

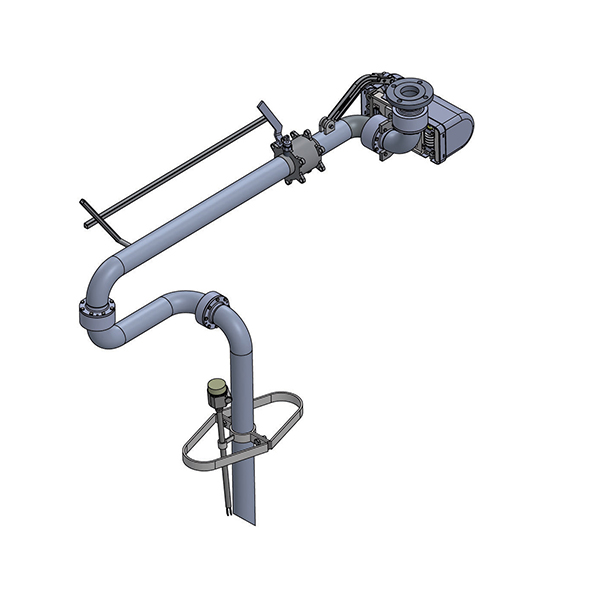

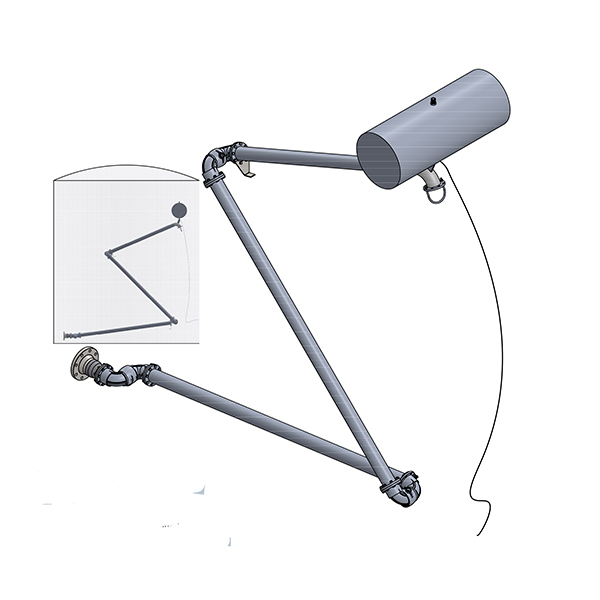

Top loading arms are used when the connection to the vehicle is made from the upper part of the truck or railcar. They are common in installations where top access is required or when the operating process demands it, providing high versatility and direct visual control during loading.

Bottom loading arms, on the other hand, connect to the outlets located at the lower part of the vehicle. This system is widely used in modern terminals as it offers improved operational safety, a significant reduction in vapours and faster loading and unloading operations.

Gassó designs and manufactures both top loading arms and bottom loading arms, advising customers to select the most suitable solution according to the product, applicable regulations and installation layout.

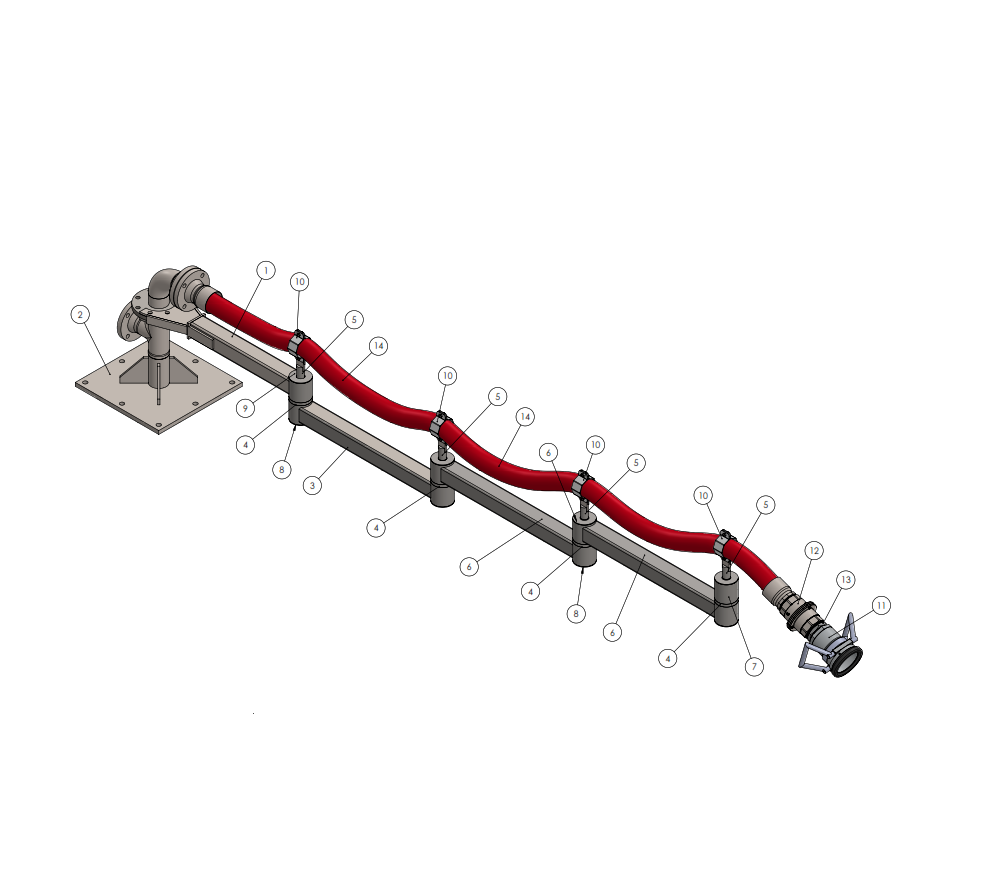

Types of loading arm and common configurations

The range of Gassó loading arms allows for multiple configurations and typologies, adapted to the real needs of each customer. Starting from standard solutions, specific configurations are developed taking into account the available space, required reach and operating conditions.

Common configurations include:

- Single loading arms for one product line.

- Double loading arms, designed to operate two lines or services simultaneously.

- Custom configurations based on loading heights, movement ranges and vehicle type.

Thanks to its engineering and manufacturing capabilities, Gassó can adapt each loading arm in terms of lengths, angles, rotation direction and geometry, ensuring optimal integration into the installation.

Materials and product compatibility

Material selection is a key aspect in the design of Gassó loading arms, as it determines their strength, durability and compatibility with the transferred product.

Depending on the application, loading arms can be manufactured in:

- Aluminium, for its light weight and ease of handling.

- Stainless steel, recommended for corrosive products or demanding applications.

- Carbon steel, for standard industrial uses.

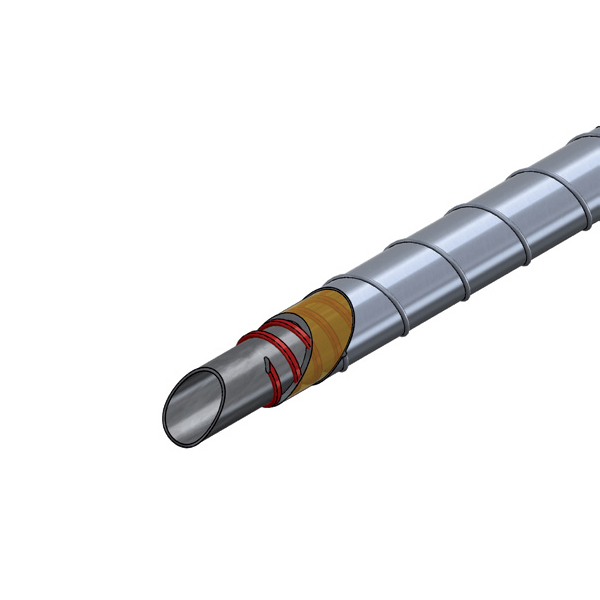

For particularly aggressive products, Gassó offers PTFE-lined loading arms, which improve chemical resistance and facilitate cleaning operations. The material is always selected according to the fluid, operating temperature and environmental conditions.

How to choose a loading arm

Selecting the right loading arm requires a prior technical analysis. Gassó’s team provides professional and experienced advice when defining the equipment, taking into account factors such as:

- Type of operation: loading or unloading.

- Use of top loading arms or bottom loading arms.

- Operating frequency and duty cycle.

- Type of product and chemical compatibility.

- Vehicle height and geometry.

- Regulatory and safety requirements.

- Environmental conditions of the installation.

This approach makes it possible to provide a solution tailored to each project, avoiding oversizing and improving operational efficiency.

Operator safety, ergonomics and access

Operator safety is a fundamental pillar in the design of Gassó loading arms. For this reason, systems can be integrated with platforms, folding stairs, safety cages and access systems, designed to ensure safe and ergonomic operation.

These solutions improve access to the loading point, reduce the risk of falls and allow comfortable operation even in high-level installations. Gassó’s experience in this type of application makes it possible to design complete assemblies in which the loading arm and access systems work together, always prioritising operator safety.

Swivel joints and critical loading arm components

Swivel joints are one of the most critical components of a loading arm. Gassó pays special attention to the design and manufacture of these elements, as they directly affect movement smoothness and overall durability.

An optimised swivel joint design ensures:

- Smooth and controlled movements.

- Wide rotation range.

- Reduced component wear.

- Lower maintenance requirements.

The quality of these components is essential to guarantee reliable long-term operation, even in intensive service environments.

Gassó manufacturing, engineering and service

As a leading manufacturer of fluid transfer solutions, Gassó goes beyond simply supplying equipment. Each loading arm is part of a comprehensive solution that includes engineering, manufacturing and specialised technical support.

From the initial project study to equipment delivery, Gassó supports customers throughout the entire process, providing tailor-made solutions adapted to the real conditions of each installation. This approach helps optimise operations, improve safety and extend the service life of the equipment.

Quality and regulatory compliance

Gassó loading arms are designed and manufactured in accordance with international quality and safety standards, complying with the regulations applicable to each sector. A strong commitment to quality and continuous improvement ensures reliable, safe solutions aligned with the requirements of the most demanding industrial installations.