Building

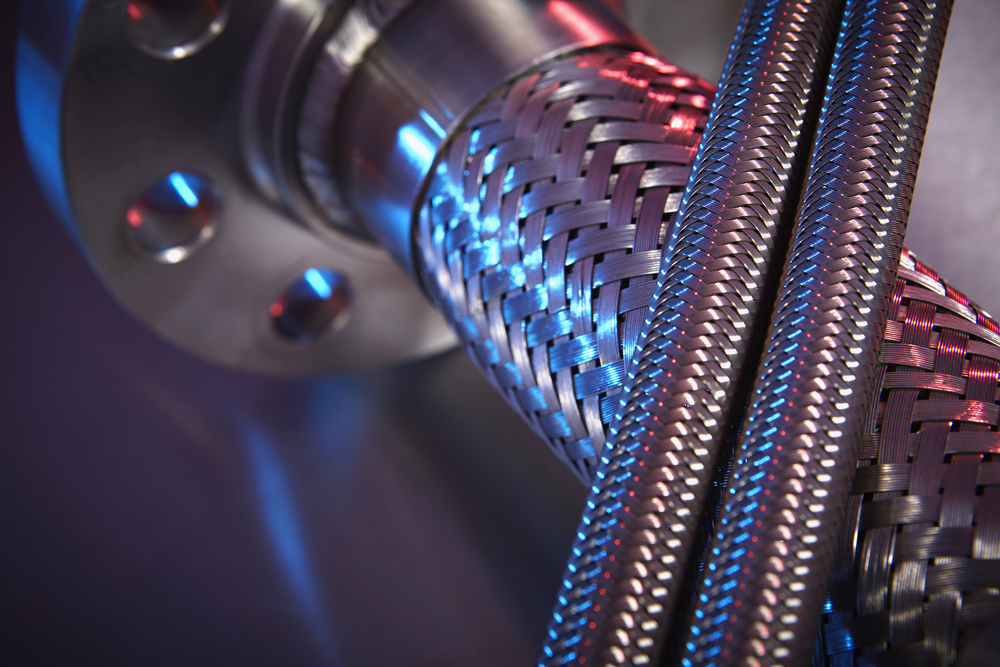

Gassó’s flexible stainless steel hoses, Gassoinox, are highly flexible and extremely resistant tubes, against pressure, against internal chemical corrosion and against external abrasion. This is possible thanks to the combination of two flexible and stainless steel construction elements: an inner corrugated tube and one or two outer braids.

Flexible pipes

The manufacture and production of pipes is governed by the standards BS5750-II / ISO9002 / 316S11 / EN10088 / 1.4541-1.4404 All Gassoinox manufactured in our facilities are tested according to DIN3.1.B / EN 10204, issuing a quality certificate and Tests of each execution.

Mounting accessories

The assembly between couplings and hoses made under the AXME-IX standard, following its welding and homologation procedure of welders and under specifications C.E. The method used is made by TIG system with INOX AISI 316 and Argon chamber protection according to BS4870 standards, ensuring the total quality of the welds.

AISI 316 (1.4404) stainless steel, parallel-wave flexible hoses, with a high degree of flexibility and high working performance, designed for demanding work at high pressures, maximum flexibilities and absorption of vibrations. Wire braid in stainless steel of 1.5 mm in AISI 304 (1.4404). Standards manufacture tube ISO 10.380 / 1 -BS6501 / 1991.B

TECHNICAL CHARACTERISTICS Continuous temperature range:

-200º to + 800º

Working pressures:

Up to 300 bar.