Scrapers

Scrapers: Cleaning systems for industrial pipes

Do you need technical advice?

Scrapers for industrial pipelines: what they are and what they are used for

Scrapers for industrial pipelines are devices designed for internal cleaning, sweeping and product recovery in industrial piping systems. They move through the inside of the pipe driven by the process fluid or by a propulsion medium, dragging residues and deposits accumulated on the internal wall.

Their use is common in installations where process efficiency, internal line cleanliness and reduction of product losses are critical factors.

Scrapers for pipeline cleaning: operating principle

Scrapers for pipeline cleaning operate by travelling along the line, adapting to the internal diameter and exerting a mechanical scraping action on the residues present.

During their travel, the scraper pushes remaining product, condensates or dirt towards the outlet point, facilitating pipe cleaning and improving system performance.

When to use industrial pipeline scrapers

The use of industrial pipeline scrapers is especially recommended in situations such as:

- Product changeovers within the same line.

- Reduction of residual product after transfer operations.

- Line preparation prior to maintenance activities.

- Improving internal cleanliness without dismantling the installation.

These applications help optimise time, reduce waste and improve operational efficiency.

Types of industrial pipeline scrapers

There are different types of scrapers depending on the objective of the operation and the design of the installation:

- Cleaning scrapers, aimed at removing adhered residues.

- Sweeping scrapers, designed to push remaining product.

- Product recovery scrapers, used to minimise losses.

Each type is selected according to the fluid, the required level of cleanliness and the geometry of the pipeline.

Scraper materials and design

The design and materials of the scraper directly influence its behaviour during operation. Elastomeric materials or technical polymers are commonly used, offering a good balance between flexibility, resistance and cleaning efficiency.

Material selection must consider compatibility with the product, operating temperature and the expected level of abrasion.

Diameters, passage through fittings and installation limitations

Scrapers for industrial pipelines must be matched to the internal diameter of the line to ensure effective cleaning and controlled movement.

The presence of bends, valves, reducers or other components that may affect scraper passage should be carefully evaluated to determine the feasibility of the operation.

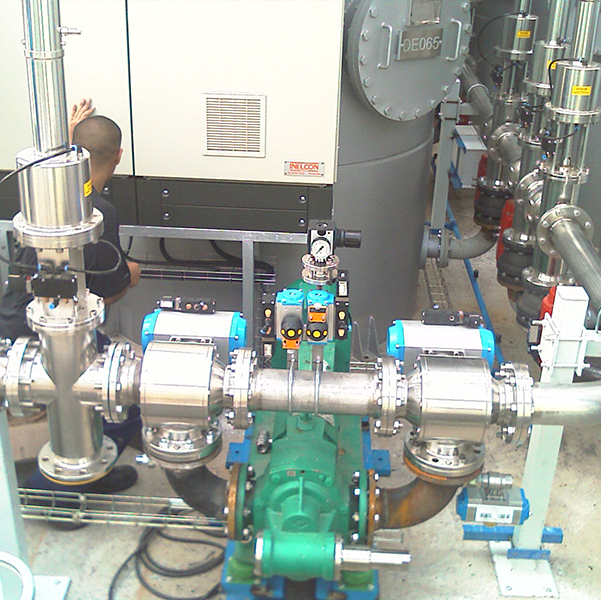

Launching and receiving stations

To carry out cleaning operations safely and repeatedly, installations may incorporate scraper launching and receiving stations.

These access points allow the scraper to be introduced and retrieved in a controlled manner, improving operator safety and facilitating cleaning process management.

Typical industrial applications

Industrial pipeline scrapers are used across various sectors where internal cleanliness and transfer efficiency are essential:

- Chemical and petrochemical industries.

- Liquid product transfer processes.

- Industrial installations with shared pipelines.

How to choose scrapers for industrial pipelines

Selecting a scraper for industrial pipelines should be based on a prior technical assessment that considers:

- Operation objective: cleaning, sweeping or product recovery.

- Type of fluid and compatibility with the scraper material.

- Pipeline diameter, length and geometry.

- Frequency of use and operating conditions.

Proper selection ensures a safe and effective operation.

Integration within the transfer system

Scrapers form part of a complete fluid transfer system that includes hoses, couplings and auxiliary components.

Correct integration helps optimise installation performance and improve overall efficiency.

Gassó technical support for industrial scrapers

Gassó brings its experience in fluid transfer solutions, advising on the selection of scrapers for industrial pipelines tailored to each application.

A technical approach and system-level knowledge enable coherent, safe and installation-specific solutions.