Gassoflex Hoses

The only manufacturer of composite hoses in Spain. Six automatic lines to manufacture any model from 1“ to 12”.

Do you need technical advice?

What are Gassoflex hoses?

Gassoflex hoses are composite hoses designed for the safe transfer of industrial fluids in demanding applications. In the industry, the term composite hose refers to this type of solution compared to traditional rubber hoses, highlighting its multi-layer construction, high chemical resistance and excellent flexibility.

Manufactured entirely by Gassó at its Sant Boi de Llobregat (Barcelona) plant, Gassoflex hoses are intended for handling hydrocarbons, chemicals, biofuels, gases and vapours, as well as high- and very low-temperature applications, both in fixed and mobile installations.

Gassoflex composite hose technology

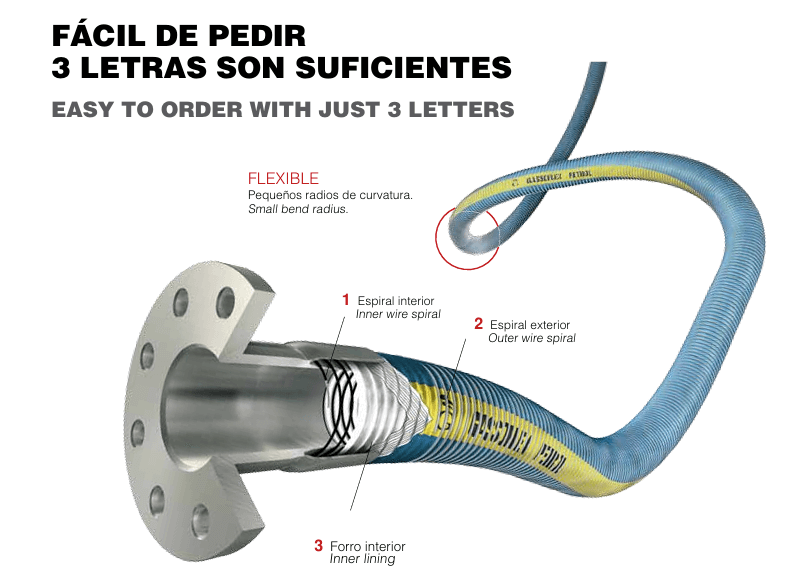

Gassoflex technology is based on a multi-layer composite hose structure made up of three main elements:

- Inner wire spiral, providing mechanical strength and structural stability.

- Outer wire spiral, reinforcing the hose against traction, crushing and intensive use.

- Inner lining, in direct contact with the conveyed product, selected according to the required chemical and thermal compatibility.

This construction allows the Gassoflex composite hose to deliver a tight bend radius, high flexibility even in large diameters, and reliable performance in both suction and delivery.

The Gassoflex range uses a three-letter identification system that clearly defines the materials of each composite hose and makes it easier to select the right option for each specific application.

Industrial applications for Gassoflex composite hoses

Gassoflex composite hoses are designed to cover a wide range of industrial applications, including:

- Transfer of hydrocarbons and fuels

- Handling of chemical products

- Biofuels, alcohols and ethanol

- Aviation applications (Jet A1, kerosene)

- Vapour recovery

- Marine and port operations

- Cryogenic applications (LPG, LNG)

- High-temperature processes (thermal oils, bitumen, hot air)

These composite hoses are commonly used in tank trucks, rail tank cars, loading terminals, industrial plants, ports and airports, where safety and reliability are critical.

Available materials and configurations

The Gassoflex composite hose range offers multiple configurations to suit each operating environment:

- Inner and outer spirals in galvanized steel, stainless steel, aluminium or coated steel.

- Inner linings in polypropylene (PP), PTFE or polyamide, depending on the conveyed product.

- Inside diameters from 1” to 10”.

- Standard lengths in coils up to 30 metres, with options available on request.

- Options for customisation in colours, grades and special configurations.

This versatility makes the Gassoflex composite hose a solution suitable for both standard applications and specific projects.

Safety, standards and certifications

Gassoflex composite hoses comply with major international standards, ensuring use in regulated industrial environments:

- EN 13765 and EN 13766

- IMO IBC Codes

- PED 2014/68/EU

- ATEX (Zones 1, 2, 21 and 22)

- ISO 9001 quality system

Gassó operates an in-house testing laboratory, where controls and tests are performed to ensure the performance, safety and traceability of every composite hose prior to delivery.

Operational advantages of composite hoses vs. other solutions

Using Gassoflex composite hoses provides clear advantages over traditional solutions:

- Lower weight and easier handling.

- Excellent flexibility, even in large diameters.

- High chemical and thermal resistance.

- Longer service life and reduced maintenance.

- Large permanent stock for shorter lead times.

These advantages help improve operational safety and efficiency in fluid transfer operations.

Technical support and tailor-made solutions

Beyond supplying composite hoses, Gassó provides specialised technical support to help select the right hose for each application.

Gassoflex hoses can be supplied with fittings and accessories, as well as in customised assemblies for specific projects, ensuring a complete, safe and application-focused solution.