Fittings

Wide range of fittings in stock for all sectors and applications.

Filters

Do you need technical advice?

Industrial couplings: critical elements in an installation

Industrial couplings are fundamental connection components in fluid conveying and transfer systems. Their function is to connect hoses, pipes or equipment in a safe, tight and reliable way, ensuring process continuity even under demanding operating conditions.

Proper coupling selection directly affects installation safety, assembly durability and the prevention of leaks or accidental disconnections.

Couplings and fittings for hoses: tightness, safety and fast connection

In industrial applications, couplings must ensure an effective connection between the hose and the system, maintaining tightness even under pressure, vibration or temperature changes.

In addition, many processes require frequent and repetitive connections, making it essential to use couplings designed to simplify handling without compromising safety.

Main types of industrial couplings in the Gassó range

The Gassó industrial couplings range covers the most widely used standards in fluid transfer, adapting to different sectors and levels of demand.

Common types include TW DIN 28450, Camlock, Autolock, Guillemin and Storz couplings, as well as specific couplings for steam, air, food processing and sanitary applications.

TW DIN 28450 couplings

TW DIN 28450 couplings are among the most commonly used standards in industrial transfer installations. They provide a robust and reliable connection, particularly suitable for large-diameter hoses and demanding applications.

Their design makes them a common solution in sectors such as chemical, petrochemical and energy industries.

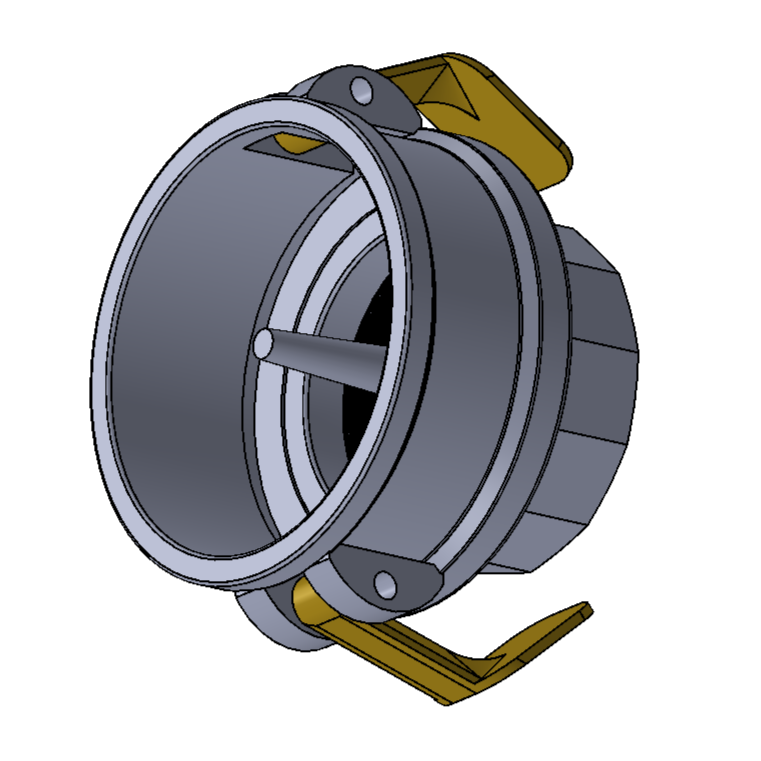

Camlock couplings: quick connection for frequent operations

Camlock couplings stand out for their ease and speed of connection, making them ideal for operations with a high frequency of coupling and uncoupling.

They are widely used across many industrial sectors thanks to their versatility and the availability of different configurations and materials.

Autolock: safety couplings

Autolock couplings are designed to minimise the risk of accidental disconnections. They incorporate an automatic locking system that increases operational safety.

This type of coupling is especially suitable for applications where operator safety and system integrity are critical.

Guillemin couplings

Guillemin couplings are symmetrical couplings widely used in industrial and fluid transfer applications. Their design allows a simple and reliable connection between hoses and equipment.

Storz couplings

Storz couplings are commonly used in pumping applications, industrial services and firefighting systems, where a fast and secure connection is required.

Steam couplings and DIN 2817 safety clamps

For applications involving steam and high temperatures, specific couplings are available that are designed to withstand demanding thermal conditions.

DIN 2817 safety clamps complement these solutions, providing additional retention that increases assembly reliability.

Barcelona couplings and couplings for compressed air

Barcelona couplings UNE 23400 are commonly used in water and industrial service applications, while compressed air couplings enable quick connections in pneumatic systems.

Sanitary couplings and food applications

In sectors such as food and pharmaceutical industries, sanitary couplings are used, designed to meet hygiene and cleaning requirements.

These couplings allow safe product transfer, maintaining process integrity and facilitating cleaning operations.

Materials and finishes in industrial couplings

Industrial couplings can be manufactured in different materials depending on the application: stainless steel, aluminium, brass or carbon steel.

Material selection affects chemical resistance, durability and compatibility with the fluid.

Seals and chemical compatibility

Seals are a key component in ensuring coupling tightness. Their selection must be based on the product, temperature and service conditions.

Materials such as EPDM, NBR, PTFE, Viton or silicone make it possible to adapt the coupling to a wide range of industrial applications.

How to choose suitable industrial couplings

Selecting industrial couplings should be based on a technical analysis of the application:

- Type of fluid and chemical compatibility.

- Working pressure and temperature.

- Frequency of connection and disconnection.

- Applicable standards and safety requirements.

- Type of hose or equipment to be connected.

Integration with industrial hoses

System performance depends on the correct integration between coupling and hose. Proper assembly reduces the risk of leaks, improves safety and extends the service life of the assembly.

Standards, standardisation and traceability

Industrial couplings are used in regulated environments where standardisation and traceability are essential.

Compliance with standards facilitates the integration of couplings into complex industrial installations.

Custom manufacturing and Gassó technical support

Gassó brings its expertise in fluid conduction solutions, offering industrial couplings selected and configured according to the real needs of each application.

Technical support and adaptability make Gassó a reliable partner for demanding industrial projects.