Couplings

We manufacture different dry couplings for industry.

Filters

Do you need technical advice?

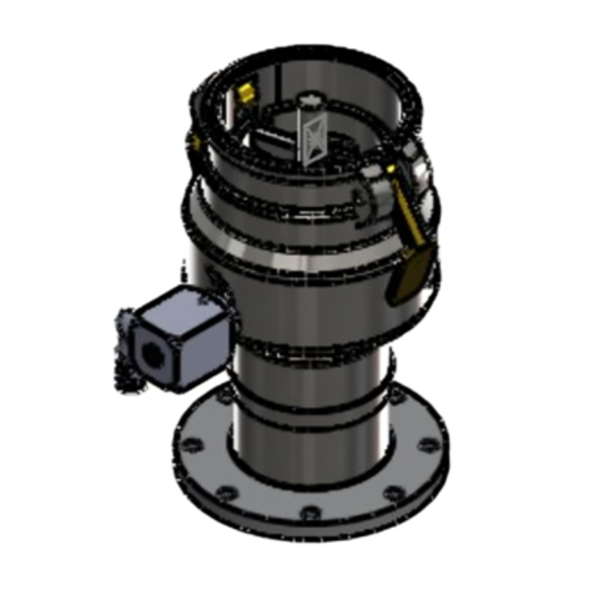

Dry disconnect couplings: what they are and why they are key to safe fluid transfer

Dry disconnect couplings are connection systems designed to allow the loading and unloading of fluids without spills, even during the connection and disconnection of hoses or process lines. Their main purpose is to ensure operator safety, product protection and the prevention of accidental emissions or leaks.

In industrial installations where chemical, flammable or high-value products are handled, dry disconnect couplings are an essential element to ensure a clean, controlled operation that complies with current safety requirements.

How dry disconnect couplings work

The operation of dry disconnect couplings is based on a system of automatic internal valves integrated into both halves of the coupling. During connection, the valves open in a controlled manner, allowing fluid flow only when the coupling is fully engaged.

During disconnection, the system works in reverse: the valves close automatically before the halves separate, preventing product release from both the line and the hose or mobile equipment.

Advantages of using dry disconnect couplings over traditional systems

The use of dry disconnect couplings instead of conventional connections provides significant operational and safety advantages:

- Elimination of spills during connection and disconnection.

- Greater operator safety, reducing exposure to the product.

- Protection of the environment and the installation.

- Reduced time required for cleaning and maintenance.

- Improved efficiency in loading and unloading operations.

Types of dry disconnect couplings available in the Gassó range

The Gassó dry disconnect coupling range includes different solutions designed to adapt to the requirements of each industrial application. There are models suitable for different flow rates, levels of demand and installation types.

From compact solutions to full-flow systems, dry disconnect couplings are configured according to process needs, always maintaining the principle of spill-free connection.

Dry disconnect couplings by application and level of demand

Dry disconnect couplings are used across a wide range of industrial sectors, especially where process safety and cleanliness are critical:

- Chemical and petrochemical industry.

- Processes involving hazardous or corrosive products.

- Food and pharmaceutical industries.

- Transfer of high-value products.

- Frequent loading and unloading operations.

Materials, seals and product compatibility

Material selection is a key factor in the performance of dry disconnect couplings. Depending on the product and the environment, couplings can be manufactured in stainless steel, aluminium or other specific materials.

Seals play a fundamental role in system tightness. Their chemical and thermal compatibility must be carefully evaluated to ensure safe and long-lasting operation.

Flow rate, pressure drop and full-flow design

Many dry disconnect couplings are designed with a full-flow concept, allowing high flow rates and minimising pressure loss during fluid transfer.

This design is especially important in fast loading and unloading operations, where process efficiency is a determining factor.

How to choose the right dry disconnect coupling

Selecting the right dry disconnect coupling should be based on a technical analysis of the process. Key aspects to consider include:

- Type of product and chemical compatibility.

- Operating pressure and temperature.

- Required flow rate.

- Frequency of connection and disconnection.

- Regulations and safety requirements of the installation.

Specialised technical advice helps ensure the safest and most efficient solution for each application.

Operational safety and operator protection

Dry disconnect couplings are designed to significantly improve safety during fluid transfer operations. By preventing spills and splashes, direct operator exposure to the product is reduced.

This improvement in working conditions contributes to safer industrial environments and a reduction in the risk of incidents.

Integration with hoses, loading arms and existing systems

Dry disconnect couplings form part of a complete system that includes industrial hoses, loading arms and fixed or mobile equipment.

Proper integration of the coupling within the system ensures reliable and consistent operation of the entire installation.

Standards, certifications and regulated environments

Dry disconnect couplings are commonly used in regulated industrial environments, where compliance and traceability are essential requirements.

Having solutions designed for these environments enables safer and more confident operation.

Engineering, experience and Gassó dry disconnect solutions

Gassó brings its experience in fluid transfer solutions, supplying dry disconnect couplings integrated into real loading and unloading systems.

Technical expertise, selection capability and specialised support make Gassó the ideal partner for demanding industrial projects.

Gassó: dry disconnect couplings for spill-free fluid transfer

The Gassó dry disconnect coupling range is designed for processes where safety, cleanliness and reliability are non-negotiable. Solutions developed to ensure efficient, spill-free fluid transfer in demanding industrial environments.