Breakaways Couplings

We manufacture breakaway type safety couplings from 1-1/2“ to 12”.

Do you need technical advice?

Safety breakaway couplings: what they are and why they are essential

Safety breakaway couplings are safety couplings designed to protect people, equipment and installations during loading and unloading operations with mobile points, such as tank trucks, vessels or trains. They are typically installed between the hose (or the loading arm) and the mobile point, with the aim of preventing spills and damage in the event of incidents such as accidental pull-away or abnormal pressure conditions.

In demanding industrial environments, where flammable, corrosive or high-risk products are handled, safety breakaway couplings provide an additional layer of protection: they act exactly when needed, reducing the risk of hose rupture, damage to the installation and product leakage.

How a safety breakaway coupling works

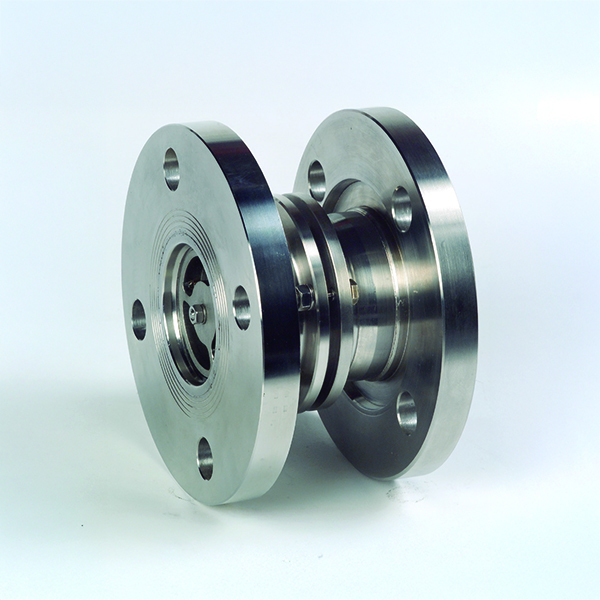

The safety BreakAway system consists of two symmetrical parts joined together by weakened bolts. Under normal operating conditions, both halves remain connected and the fluid flows through the coupling without restriction.

In the event of accidental stretching or excessive pressure, the bolts break before the hose or loading arm, causing a controlled separation. When the parts separate, the flow is automatically shut off by internal flaps, so that each half remains sealed at its end: one on the installation side and the other on the vehicle. The result is clear: spill prevention and effective protection of the fluid transfer system.

Industrial applications of Gassó breakaway couplings

Gassó safety breakaway couplings are recommended for a wide range of sectors and processes where transfer safety is critical. They are used in loading and unloading operations within the chemical and petrochemical industries, as well as in food, pharmaceutical and energy-related applications.

Their role is especially important when handling flammable, corrosive, toxic or high-risk products, and when the installation relies on technical hoses or loading arms that must be protected against accidental pull-away situations.

Safety breakaway couplings for the chemical industry

In the chemical industry, breakaway safety couplings offer a key advantage: they help prevent leaks and spills during operations where an accidental disconnection could have serious consequences for personnel safety, environmental protection and process continuity.

Gassó designs and supplies safety breakaway couplings with material and sealing options aimed at improving compatibility with demanding chemical products, including solutions with Viton, EPDM, PTFE or Kalrez seals, depending on the specific application requirements. This approach allows the system to be configured in line with the product, temperature and real operating conditions.

Safety breakaway couplings for cryogenic applications

For LPG, LNG and cryogenic gas lines, Gassó offers a dedicated solution of safety breakaway couplings designed for extreme operating conditions. In these applications, where temperatures can be extremely low, sealing reliability and system behaviour are especially critical.

Cryogenic breakaway couplings are designed for operations such as ship-to-shore, ship-to-ship loading and unloading, as well as for trucks and railway applications. They incorporate a special cryogenic seal, provide high flow rates with low pressure drop, and feature a robust and lightweight design to ensure safe operation in demanding installations.

Materials, sizes and connection types

Gassó safety breakaway couplings can be supplied in different configurations to suit the installation and the type of product handled. For standard applications, options are available in aluminium and stainless steel 316L, with other materials available on request.

Regarding connections, breakaway couplings can be integrated using BSP or NPT threads as well as common industrial flanges, such as TTMA, ASA or DIN, making them suitable for both new projects and retrofitting existing systems.

Operational advantages of BreakAway safety couplings

The use of safety breakaway couplings provides direct benefits in terms of safety and operational efficiency:

- Spill prevention in the event of accidental pull-away or operational incidents.

- Protection of hoses, loading arms and fixed installations against damage and breakage.

- A system designed to act reliably and keep the assembly sealed at both ends.

- Easy reassembly after activation, requiring only the replacement of the bolts.

- Reduced costs related to cleaning, downtime and replacement of damaged equipment.

Gassó engineering, manufacturing and in-house quality laboratory

At Gassó, customer safety is a top priority. For this reason, the BreakAway system is not considered a simple accessory, but a solution developed based on extensive experience in fluid transfer. As a manufacturer, Gassó designs safety breakaway couplings with a practical approach: proven field reliability, seamless integration with hoses and loading arms, and ease of maintenance.

In addition, Gassó operates its own engineering department, manufacturing facilities and quality laboratory, enabling thorough validation of system performance and full control over the final product. This level of control is especially important in critical applications, where repeatability and safety cannot be compromised.

Regulatory compliance and certifications

Gassó safety breakaway couplings are designed for use in regulated industrial environments. Compliance with applicable standards and the availability of configurations adapted to different sectors make it possible to integrate these safety couplings into installations where safety and traceability are essential requirements.