Accessories

We manufacture and distribute all types of accessories for our hoses, with a large permanent stock of all our products.

Do you need technical advice?

Accessories for industrial hoses: why they make the difference

Accessories for industrial hoses are key components to ensure proper operation, safety and durability of fluid transfer systems. Although they are often considered secondary elements, their role is decisive in the overall performance of the installation.

From initial assembly to daily operation, accessories allow the hose to be adapted to real process conditions, improve operational safety and extend the service life of the complete assembly.

Accessories and safety: reducing leaks, failures and operational risks

Proper selection of industrial hose accessories directly contributes to reducing leaks, accidental disconnections and damage to the installation.

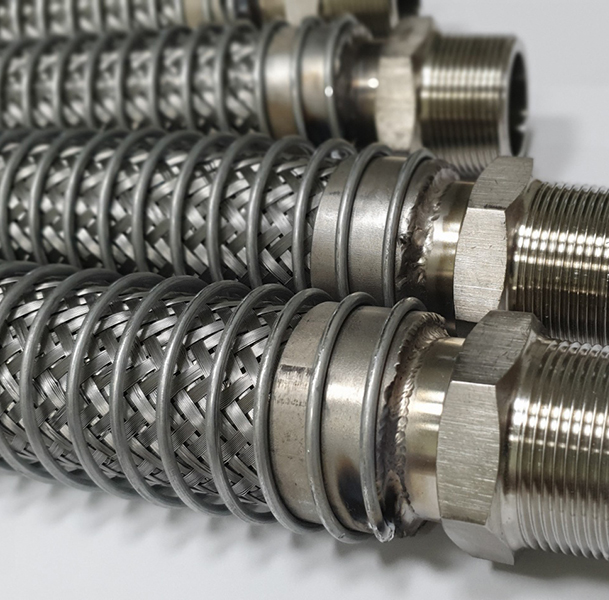

Components such as clamps, protective elements or sealing systems help maintain tightness, absorb stresses and protect the most critical points of the system, improving operator safety and environmental protection.

Industrial hose accessories for assembly and fixing

Assembly and fixing accessories ensure the correct connection between the hose, the coupling and the equipment. Their function is to keep the connection stable even under pressure, vibration or repetitive movement conditions.

Clamps, brackets and fixing systems prevent slippage, loss of tightness and undue stress on the hose.

Clamps and fixing systems: how to choose the right type

Clamps are among the most commonly used accessories in industrial hoses. Their correct selection must take into account factors such as hose diameter, working pressure, type of fluid and service conditions.

A suitable fixing system ensures a secure hold without damaging the hose or compromising its flexibility.

Seals, sealing and tightness

Seals play an essential role in system tightness. Although they are small components, their impact on safety and reliability of the assembly is critical.

Chemical compatibility, working temperature and pressure must be considered when selecting the seal material, ensuring effective and long-lasting sealing.

Hose protectors: abrasion, bending and fatigue points

Hose protectors are designed to protect the areas most exposed to wear, especially at the coupling connection point and in zones subject to abrasion or repeated bending.

These accessories help prevent premature damage, reducing the risk of failure and extending the service life of the industrial hose.

Accessories for control and operation

In certain applications, accessories play a direct role in operation, allowing flow control, easier handling or improved safety during use.

Nozzles, valves and other service components fall into this category, adding functionality to hose systems.

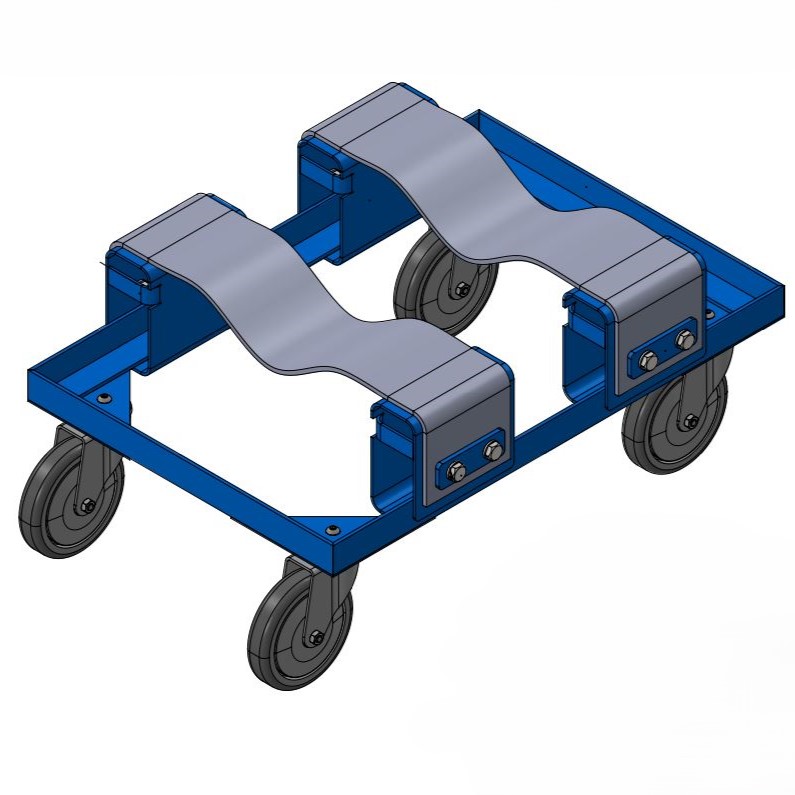

Accessories for hose management and organisation

Proper hose management is key to safety and efficiency. Accessories designed for organisation and storage help prevent damage, tripping hazards and unnecessary handling.

These elements support cleaner, more organised and safer operations in industrial environments.

Accessories for adaptations and transitions

In many installations, it is necessary to adapt diameters, connection types or existing configurations. Adaptation accessories make it possible to carry out these transitions without compromising safety or system performance.

Reducing incompatibilities and facilitating hose integration into the installation is one of the key roles of this type of accessory.

How to choose accessories for industrial hoses

Selecting accessories for industrial hoses should be based on a technical analysis of the application:

- Type of fluid and chemical compatibility.

- Working pressure and temperature.

- Frequency of use and operating conditions.

- Installation environment and applicable standards.

- Type of hose and couplings used.

A global approach avoids selection errors and improves system reliability.

Integration with couplings and hoses: the system as a whole

Accessories should not be considered isolated elements, but part of a complete system made up of hoses, couplings and safety components.

Proper integration of all components reduces failures, improves safety and optimises installation performance.

Gassó technical support for industrial hose accessories

Gassó brings its expertise in fluid transfer solutions, providing guidance in the selection of accessories for industrial hoses tailored to each application.

Technical support and system-level knowledge enable Gassó to deliver coherent, safe and durable solutions for demanding industrial environments.